New pre-GMP laboratory in Bergen

Strengthening Norway’s ATMP infrastructure

A new pre-GMP laboratory is being established in Bergen as part of the ATMP Norway initiative, supported by a NOK 50 million grant from the Research Council of Norway. The pre-GMP laboratory will help bridge the gap between research and clinical application of advanced therapies, strengthening Norway’s infrastructure for cell- and gene-based medicines.

The Research Council of Norway has granted NOK 50 million to establish new infrastructure for developing medicines based on genes, tissues, and cells through the project ATMP Norway. The project includes the establishment of a national quality control laboratory at Oslo University Hospital and a new pre-GMP laboratory in Bergen.

Researchers developing advanced therapies, such as innovative cell therapies, can use the pre-GMP lab for process development and testing in collaboration with qualified personnel trained in Good Manufacturing Practice (GMP). This will help ensure a smoother and faster transition from research to clinical studies that, in time, will benefit patients.

From research to clinical application

Transitioning an ATMP project from basic research to an approved clinical study is a long, complex, and costly process. The shift from preclinical to clinical studies is particularly challenging due to differences in protocols and equipment between research and clinical settings. Furthermore, limited awareness of regulatory requirements can lead to delays and increased costs.

The pre-GMP facility in Bergen will support researchers in adapting research protocols to GMP-compatible ones. Services will include process optimization, equipment testing, advisory support, and training. The lab will have restricted access and is located on the 7th floor of the BB building - strategically placed near relevant research activities at the University of Bergen and Haukeland University Hospital, including the newly established Bergen Centre for Medical Stem Cell Research (BSMS).

Once operational, researchers can order service packages tailored to their needs and expertise. These may include equipment testing, advisory services, training, and full procedure optimization. Access will be controlled, and usage will follow a national pricing model.

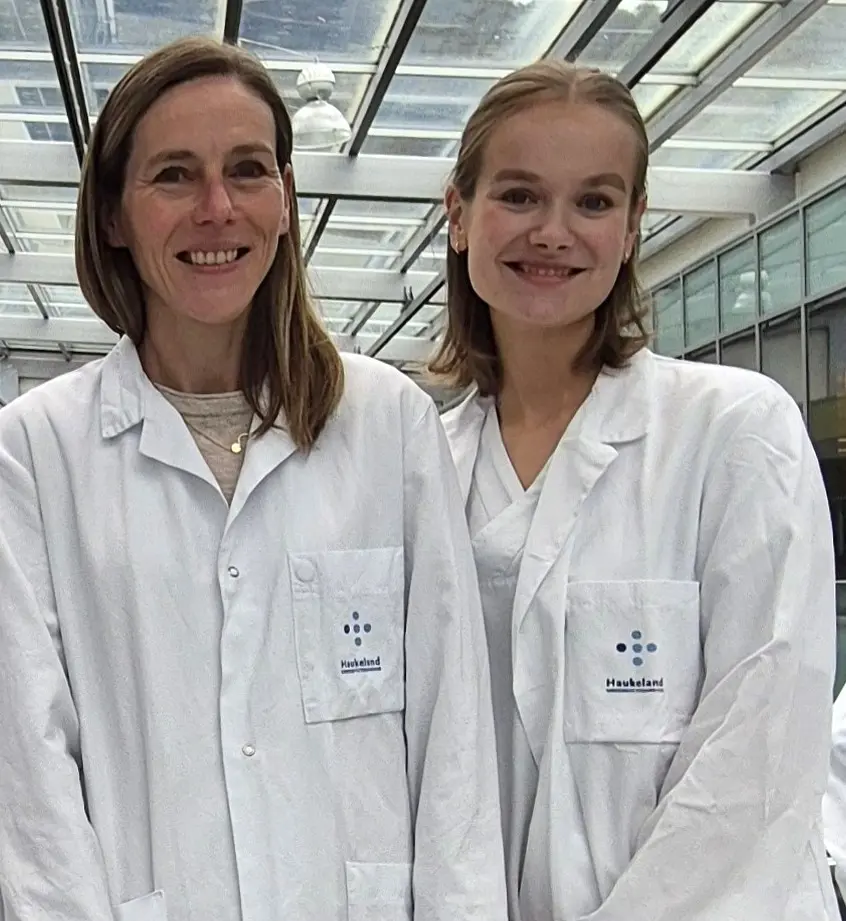

Kimberley J. Hatfield, Head of the GMP Ex-vivo facility and leader of the new pre-GMP lab, expressed gratitude for the funding:

We are very pleased that the Research Council of Norway is supporting the development of advanced therapies, enabling faster and more cost-effective progress.

Oline Øie Hovland, Facility Manager, will be responsible for the establishment and daily operations.

Photo: Elise Aasebø

Advanced therapy production at Haukeland

Several research groups at Haukeland University Hospital and the University of Bergen are developing Advanced Therapy Medicinal Products (ATMPs), which are biologically processed medicines such as cell, gene, and tissue therapies. These must be produced in cleanroom laboratories that meet GMP standards to ensure product quality and safety.

At the Laboratory Medicine and Pathology at Haukeland University Hospital, a high-grade cleanroom Ex-vivo facility has been built, operating under GMP. In this facility, the Section for Cell-Based Medicinal Products (CMP) at the Department of Immunology and Transfusion Medicine (AIT) will produce advanced therapies for clinical studies.

The first planned production involves mesenchymal stem cells (MSCs) for a project affiliated with the Mohn Research Centre for Regenerative Medicine (MRCRM). The process includes harvesting MSCs from the patient’s hip bone, expanding them under controlled conditions in the cleanroom, and reintroducing them into the patient as a biological drug. The cell product undergoes extensive quality control before release to ensure it meets all safety and quality requirements. All production steps, including quality controls, must be validated and approved before the clinical study can begin.

Infrastructure and equipment

The pre-GMP lab will be equipped with the same instruments and medical equipment as the Ex-vivo facility, including:

- LAF benches

- CO₂ incubators

- Microscopes

- Cell counters

- Sealing devices

- Flow cytometers

- Scales

- Centrifuges

- -20°C freezers and refrigerators

- Sterile welders

This setup mirrors a real GMP lab and helps researchers prepare robust, standardized protocols which can later be used for clinical cell production by GMP qualified personnel. All production steps, i.e.reagents (including lot numbers), quality control procedures and preliminary release criteria must be defined before taking the production protocol to a GMP lab.

GMP personnel are responsible for carrying out and documenting the validation processes and for the final production. They are also responsible for quality agreements, supplier qualification, environmental monitoring, and the qualification of rooms, equipment, and personnel.

Together, researchers and GMP personnel must define the quality attributes of both the product and the raw materials. GMP personnel will prepare a manufacturing agreement and can apply for a manufacturing license for the specific product (ATMP). However, they cannot take a vague research protocol and independently decide how the cell product should be manufactured. Active collaboration between researchers and pre-GMP staff is a pre-requisite for a successful translation.

The pre-GMP lab will bridge the gap between research and clinical application of advanced therapies and serve as a hub for developing new ATMP protocols, guided by experienced GMP personnel.

Expanding ATMP capacity in Norway

Einar K. Kristoffersen, Head of AIT and MRCRM, looks forward to expanding infrastructure in Bergen:

With this new infrastructure, Haukeland University Hospital can streamline the transition from early-phase ATMP protocols to clinical use, making new treatments available to patients. This hub can accelerate the development of new ATMP therapies and foster new projects and collaborations.”

Project leadership and collaboration

ATMP Norway is led by Oslo University Hospital (OUS), with Haukeland University Hospital and the University of Oslo as partners. The project is supported through the Research Council of Norway’s call for National Research Infrastructure and is the only project from Haukeland University Hospital selected in this competition.